The intensity of aggregate is an important quality in buildings that affects the strength, sustainability, and other properties of concrete and other building materials. Gravel, crushed stones, sands, and slags are examples of these aggregates and they are essential components in concrete because such substances will provide massiveness, stability as well as strength.

The article examines what aggregate density refers to and how it’s measured plus the aspects affecting it in construction undertakings. Also, we shall tackle some questions that are regularly asked about densities concerning aggregates.

1. What is Aggregate Density?

Aggregate density represents the mass of aggregate per unit volume typically given in kilograms per cubic meter (kg/m³). For example, this characteristic is vital as far as the overall density, durability, or strength of concrete is concerned. In more simple words it shows us how much substance packs into a particular space.

Different types of aggregates have different densities that depend on their composition, size, shape, and type. In fact for instance the density of natural sand is not equal to the one for crushed stone or gravel. Understanding what density your aggregate has can go a long way toward achieving the desired qualities for your final concrete product.

2. Types of Aggregates and Their Densities

Broadly, we may classify aggregates into natural and artificial types with densities that vary from each other:

- Natural Aggregates: These include sand, gravel, and crushed stone derived from natural sources such as riverbeds. These densities usually range between 1500 kg/m³ and 1800 kg/m³.

- Artificial Aggregates: They are manufactured by people themselves and they comprise materials like slag, expanded clay, and recycled concrete. The densities of these aggregates can be widely different but typically fall between 800 kg/m³ to 1200 kg/m³.

- Lightweight Aggregates: These are used to produce lightweight concrete. Properties such as expanded perlite or pumice have densities that start from around 300 kg/m³ up to about 900 kg/m³.

- Heavyweight Aggregates: These are utilized in high-density concretes like radiation shielding for example. Examples include barite in magnetite among others whose density surpasses 3000 kg/m³.

3. How to Measure Aggregate Density

To measure the density of aggregate, it is necessary to measure its mass and the volume that it occupies. The following procedure is recommended:

- Sample Preparation: Get a sample representing the entire aggregate ensuring that it is clean and dry.

- Mass Measurement: Weigh the sample using a calibrated scale and determine its mass.

- Volume Determination: Fill a known container with the aggregate only; then weigh this material alone.

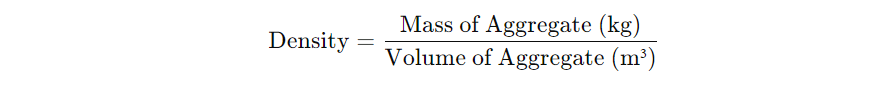

- Calculation: The density is calculated using the formula:

This process can be carried out for different aggregate sizes and types to ensure accurate results.

4. Factors Affecting the Density of Aggregate

When it comes to the density of aggregate, several factors can impact it. These include:

- Particle Size: The smaller-sized aggregates tend to be more dense because they are packed more closely. Coarser aggregates on the other hand are less dense but usually contribute to the strength of concrete.

- Moisture Content: Water in the pores of the aggregate can increase its mass and, therefore, its density. However, in case it is not properly accounted for, extra moisture can cause erroneous results.

- Shape and Texture: Angular and rough-textured aggregates have higher void content thus lower density while packed rounded and smooth particles or aggregates can fill in more tightly and hence a higher density.

- Material Composition: Aggregates made up of different minerals have varying densities. For example, those containing heavier minerals like magnetite will be denser compared to quartz ones.

5. Importance of Aggregate Density in Construction

- In designing and constructing concrete structures, aggregate density is a critical parameter; here’s why:

- Strength: Concrete with higher-density aggregates is typically stronger. This is necessary for structural elements that must support heavy loads.

- Durability: The increased denseness of such materials improves their durability, especially in harsh climatic regions where they should withstand wear and tear due to weathering actions or chemical attacks.

- Economy: The concrete mix design can be optimized by understanding aggregate density, so as to find the right trade-off between cost and performance.

- Workability: The workability of the concrete mix is also affected by aggregate density. Well-graded and dense aggregates result in a smoother mix that minimizes the need for much water or admixture.

6. Applications of Different Aggregate Densities

Various types of aggregates with various densities are suitable for different uses:

- Lightweight Aggregates: They are used in non-structural elements such as insulation or lightweight precast concrete products that require weight reduction.

- Normal Weight Aggregates: These are the most commonly employed type which is good for general construction work including foundation, flooring, and walling purposes

- Heavyweight Aggregates: They are used in specialized applications such as radiation shielding that need high density to absorb radiation.

- Recycled Aggregates: In sustainable construction, they are increasingly being utilized whose density may vary but generally falls within the normal weight range.

7. Common Mistakes in Measuring Aggregate Density

Measuring aggregate density may appear easy but several common mistakes can lead to wrong results:

- Ignoring Moisture Content: Ignoring water content in aggregate could overestimate its density.

- Improper Sampling: It is essential to use a representative sample for density measurement, otherwise the overall mix design may be affected.

- Incorrect Volume Measurement: Errors can occur in the density calculation if a container with an unknown or wrong volume is used.

- Overlooking Air Voids: Ignoring air voids among aggregate pieces may lead to low estimates of density.

8. FAQs on Density of Aggregate

Q1: What ranges of densities are typical for natural aggregates?

Depending on the material and its size distribution, the density of natural aggregates is usually in the range of 1500-1800 kg/m³

Q2: How does moisture content affect the density of aggregate?

When water is added to dry aggregate, it makes up a significant part of its total weight. However, this must be accounted for when calculating equal parts.

Q3: Why is aggregate density an important factor in concrete mix design?

Aggregate density influences strength, workability, and durability. The correct understanding and calculation of density will make it possible to ensure that concrete meets the necessary performance criteria.

Q4: Can recycled aggregates be used in high-density applications?

Recycled aggregates have generally lower densities and may not be appropriate for high-density applications. They are commonly utilized as ordinary or lightweight concretes.

Q5: How does aggregate density relate to the shape of particles?

Angular and rough-surfaced particles tend to have more voids thereby resulting in lower densities, whereas rounded particles pack more efficiently and hence have high densities.

Q6: What is the role of aggregate density in radiation-shielding concrete?

For the purpose of shielding radiation during construction, high-density aggregates such as magnetite or barite are incorporated into the mix to raise the density of concrete.

Q7: Is there a standard method for measuring the density of aggregate?

Yes, ASTM C29/C29M lists the most common standardized methods that determine bulk density (unit weight) and voids in aggregates.

Q8: How does the size of the aggregate affect its density?

The finer it is, the more filling is done by smaller grain sizes thus giving them higher densities. On the other hand, coarser materials are less dense but contribute towards the overall strength of concrete.

Q9: Can structural lightweight concretes use light-weighted aggregates?

Yes; lightweight aggregates may be used in structural concrete when low weight becomes important. However, during the design stage, reduced density must still provide enough strength.

Q10: Elucidate using lightweight aggregates in the building.

The use of low-density aggregates can decrease the total weight of structures, which may be beneficial for instance when constructing high-rise buildings or long-span bridges. However, it may also require adjusting mix designs to maintain strength and durability.

Conclusion

The density of aggregate is a fundamental concept in construction that affects everything from mix design to the integrity of the final product. When dealing with natural, recycled, or artificial aggregates, knowing their density makes it easier to create concrete that meets the required specifications and operates well under different conditions.

By considering such factors as moisture content, particle size, and composition, you can accurately determine and apply aggregate density to optimize your construction undertakings. This knowledge guarantees not only longevity and quality of the structure but also contributes towards cost-effectiveness and ecological balance.